Diamond grading explained

The appeal of diamonds is complex, blending beauty, rarity and responsible sourcing.

It is our gemmologists’ responsibility to impose a rational approach to the diamonds they consider. Using specially developed, proprietary instruments and technology, they impartially assess every diamond according to criteria based on the ‘4Cs’: colour, clarity, cut and carat.

The process of grading and assessment takes place at our laboratories in London and Surat. There, we combine over 130 years of diamond industry experience with the most advanced technology to evaluate diamonds of every size and quality. These diamonds follow our grading process, explained below, which gives the highest levels of trust and integrity possible.

OUR DIAMOND INTEGRITY PROCESS

First check

Our first line of defence when checking natural diamond integrity is DiamondSure. The device measures light absorption within the diamond, looking for a certain feature only found in naturally-grown diamonds. This feature is present in 98 percent of natural diamonds, so two per cent will be referred for further testing alongside all synthetic and simulant material.

Second check

All stones referred from DiamondSure will be checked on DiamondView, which uses a high -powered UV light to generate a surface fluorescence image of the stone, allowing us to see the growth progression and patterns. Natural diamonds, synthetic diamonds and diamond simulants all grow with different identifying characteristics, allowing us to remove any non-natural diamond material from our process.

Further test

Any stone that still requires further testing will be passed onto a physicist who will examine the diamond’s light absorption properties using spectroscopy to ensure 100 per cent diamond integrity.

OUR GRADING PROCESS

OUR TECHNOLOGY

After the integrity process and weighing, automated grading checks are carried out on each stone by our proprietary instruments which are used only in our labs.

The Falcon conducts a colour scan measuring the saturation and fluorescence intensity. It assigns a colour letter and a fluorescence grade.

OUR EXPERTISE

Colour grading is conducted by human graders using an Institute of Diamonds natural colour master stone set.

They examine the diamond using a microscope, identifying clarity, symmetry and polish features, illustrating them on a diamond plot.

Next, they view and grade the diamond with an eye loupe at 10x magnification, which is the industry standard. The graders will also evaluate the proportions, symmetry and polish grades in order to set a cut grade.

FINAL GRADING

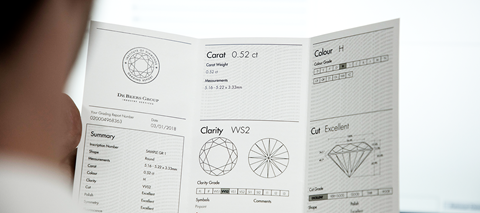

Final grading is performed by a senior grader, whose job is to review all past colour and quality results to allocate the finalised grades that will be printed on a diamond grading report.

Through our grading process, every diamond is assessed by our technologically advanced Falcon equipment and at least three different human graders.

OUR INSCRIPTION PROCESS

INSCRIPTION

After grading, a unique identification number is inscribed on the diamond by one of two methods:

1. De Beers Technology’s proprietary table inscription.

2. Our girdle inscription applied using Photoscribe technology.

SEALING

This is a service on-request that further ensures the integrity of every diamond leaving any of our global laboratories.

FINAL INSPECTION

At the final stage, the inscription is checked to ensure it has a clean finish and for security purposes, a photo is taken to record the microscopic details of the inscription. The diamond is then transferred into parcel paper, labelled with a summary and paired with the matching printed grading report, ready to go back to the customer.

For further details

REGISTER FOR A CLIENT ACCOUNT

Register for an account that will give you access to our grading services through our client portal, enabling you to submit diamonds for grading, see live updates as your shipments move through our grading process and download your grading reports 24/7.

Register here